|

LANXING TECHNOLOGY CO., LTD

|

cnc profile cutting machine

| Price: | 7000.0 USD |

| Payment Terms: | T/T,L/C |

| Place of Origin: | Hubei, China (Mainland) |

|

|

|

| Add to My Favorites | |

| HiSupplier Escrow |

Product Detail

portable cnc profile gas/flame/plasma cutting machine

cantilever cnc profile gas/flame/plasma cutting machine

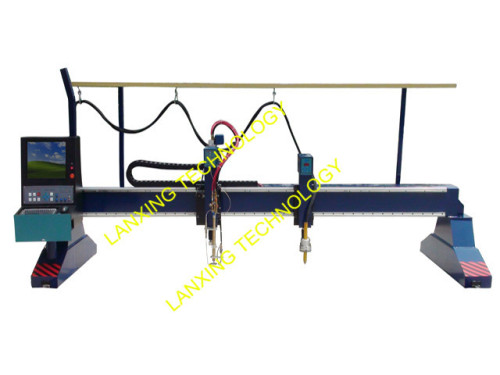

gantry cnc profile gas/flame/plasma c

Machine as showed.This model adopts gantry structure,transversal span: 3m, 4m, 5m, 6m, 8m and so on.

Can be applied in cutting carbon steel,Mn-steel,stainless steel and so on.

It can add additional cutting torches,or configurate both abnormality cutting &Strip cutting according to User Requirement.

Auto Capacitive height control for flame cutting or Arc voltage height control for plasma cutting can also be configurated.

Main Features:

1. Beam:square tube butt welding struture,excellent rigidity,high presision,lingth weight,small inertia.Prevent deformations effectively.

2. Transversal& lognitudinal drive: precision gear rack(7 grade precision)transmission. Transversal rail : linear guide imported from Taiwan, lognitudinal rail: precision machined special rail & Planet reducer to assure stable running,high presision,durable in use, clean and beautiful.

3. Lognitudinal drive rack(endframe): horizontal orientated wheel at both ends,which can adjust the puddlability between eccentric wheel and rail, to assure the stablility.With dust catcher,can clean dust on rail.

4. Drive syetem:Chinese step driver,can also configurate Japan Panasonic AC servo motor/ ChineseC servo motor.

5. THC using aluminium alloy structure,linear guide track-oriented,ball screw lift.

6. Easy automatic programming syetem.

7. Self-developed CNC system with top stability and antijamming capability.

Powerful CNC cutting machine Controller

1.Graphic display function

2.Break-point & power-cut restoration

3.Returning to reference point

4.Kerf compensation

5.Revolving

6.Mirror image

Cross Beam Length(X axis)

4m-10m

Longitudinal Rail Length(Y axis)

6m (Can be lengthened)

Effective Cutting Width (X axis)

3m-9m

Effective Cutting Length (Y axis)

4.8m(Can be lengthened)

Cutting Mode

Flame/Plasma/Both Flame&Plasma

Drive Mode

Bilateral-side

Drive Method

Rack and pinion drive for X and Y axes

Flame Cutting Thickness

5-200mm

Plasma Cutting Thickness

1-60mm (according to the specification of plasma power source)

Cutting Speed

0-3500mm per minute

.jpg)

.jpg)